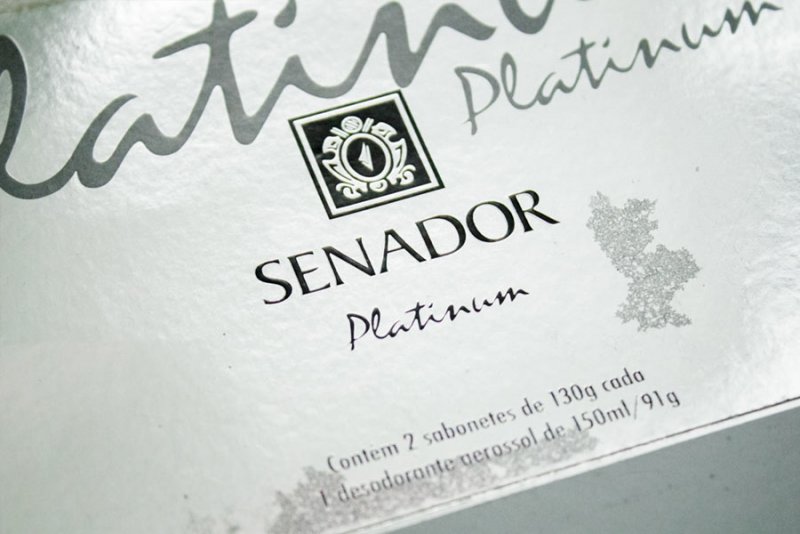

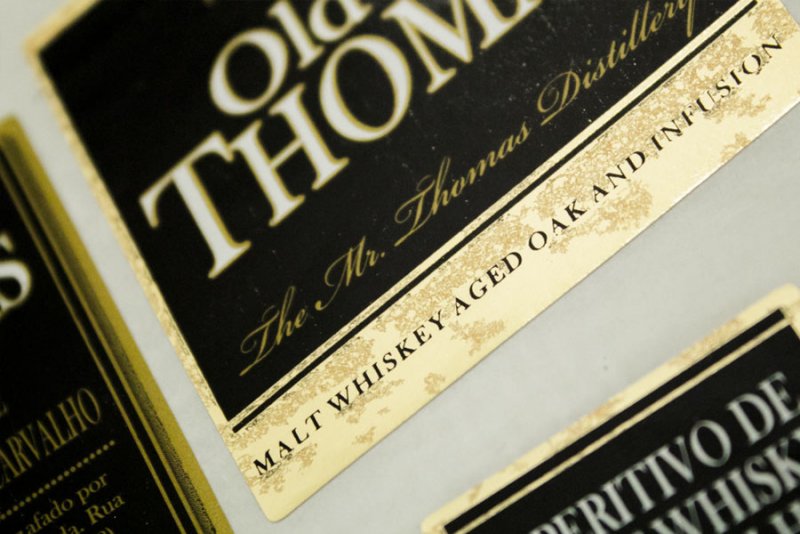

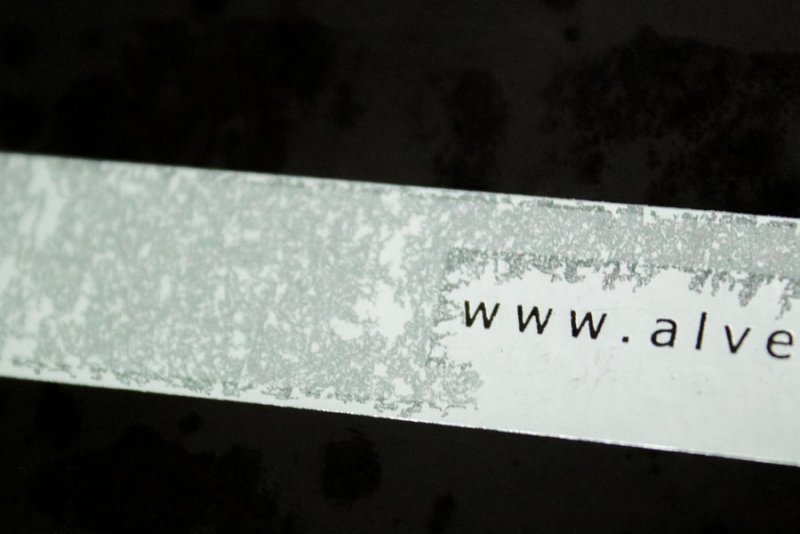

Hot Stamping Oxidation

The cause of the oxidation is the composition of the black ink, usually prepared with "black ink", which starts within five days after engraving and can last up to three months or the total disappearance of the print, as vacuum metallization, Made with aluminum filaments, it creates a barrier that prevents the paint from “breathing” and drying out completely. This problem is recurrent in the metallic hot-stamping recording process on very dark (mainly black and purple) or metallic (Metalstar or similar) inks, when some precautions that can neutralize oxidation are not observed, such as:

Do not use additives

When using this type of ink, never use additives (wax);

Wait

Wait for the ink to cure completely;

Varnish application

Apply a coat of good quality water-based varnish, with low acidity to isolate the ink from the hot-stamping tape and wait for full cure. We do not recommend the use of a water-based matte varnish for isolation/chemical barrier of the dark pigment.

Pyramid Chock

The purpose of the Pyramid Shim is to expel air from the center of the recording to the sides to avoid the holes that normally occur when hot stamping tape is applied over matte or gloss lamination in equipment that is not cylindrical (frog mouth or beat type).

Download PDF